How to control impedance circuit board

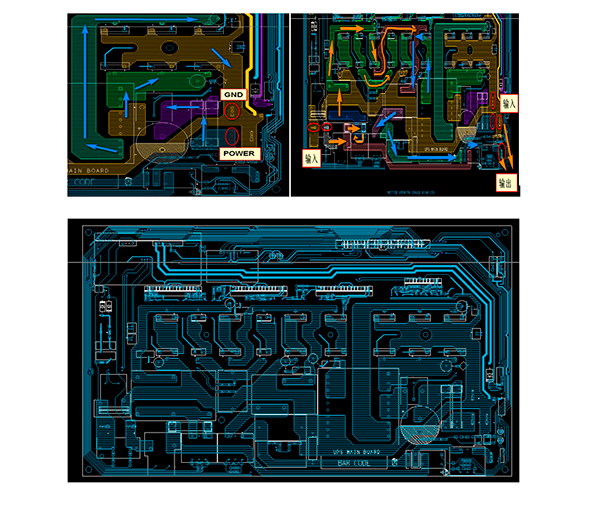

In order to execute the order correctly, it needs a precise set of dimensions and coordinates, track width, hole pattern and, of course, tolerance. Failure to comply with the given tolerance may result in rejection of the board. Nowadays, with the increasing speed of signal switching, it is very important for PCB designers to know how to consider the impedance of PCB wiring. If a trace is defined as a PCB impedance control trace, it is not the width of the trace that must be kept within a value specified by the tolerance set by the board designer, but the PCB impedance value. To meet PCB impedance requirements, manufacturers can change trace width, height, and other parameters. A PCB with impedance requirements will require a higher level of accuracy than a board without such requirements.

Changdongxin circuit uses industry standard electrode impedance calculator to calculate impedance and provide impedance report. In general, the designer calculates the impedance using the prepreg values published in the data sheet. Over the years, we have conducted extensive research to find out our "out or press" prepreg thickness, also known as extrusion thickness. Using these values will help us to improve the impedance calculation and make them closer to the actual values on the finished PCB. That's why we encourage you to work at a conceptual level with our team and experienced field application engineers so that we can help you optimize impedance calculations.

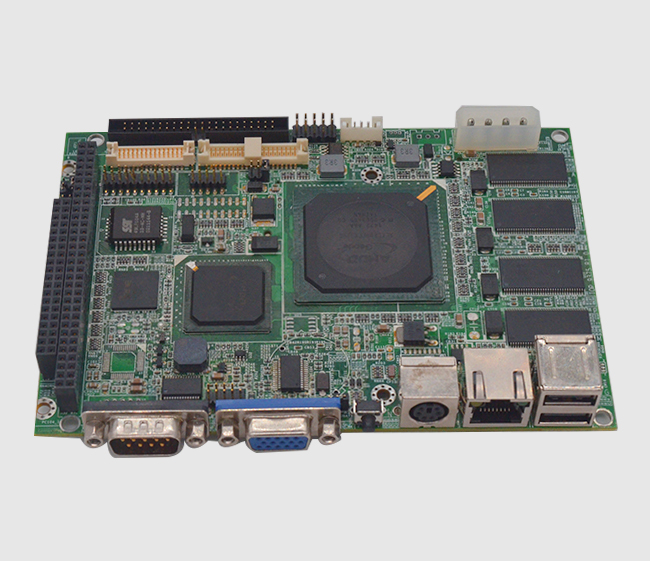

Recommended products

Latest news articles

- Zhongxin, Huawei, IMEC and Qualcomm all work together to build the most advanced integrated circuit R & D platform in China

- Looking forward to smart car chip companies busy with M & A

- Optimistic about smart car chip manufacturers busy merging Toyota's latest patent exposure: flying car research

- IPC issued the first performance requirements standard for rigid plate of automobile version